|

|

Call Toll Free (844) 239-4055 and Receive a FREE Site Plan and Consultation! |

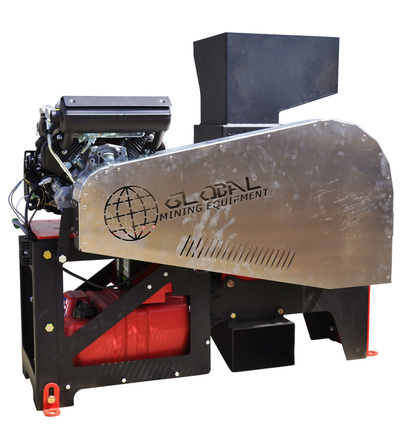

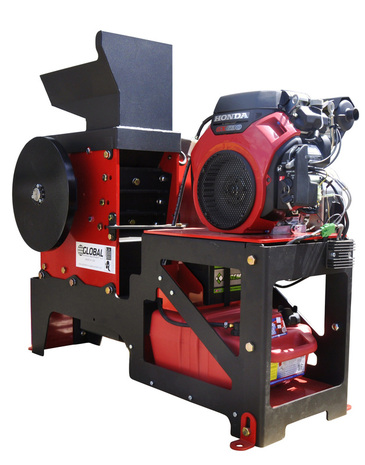

GME10 - Jaw Crusher | 10" (254mm) wide Jaw Crusher

Price:

Request a Quote

Description:

The GME10 Jaw Rock Crusher is a rock crusher that is designed to take larger rock and crush them down to 1" (25mm) or smaller to further be reduced by the GME Hammer Mill for gold milling sites. This crusher is also used by Contractors and Landscapers to crush rock for demolition or to create a specific product for use.

This jaw crusher is able to crush rock / ore up to 8" (205mm) in a very productive manner. The jaw rock crusher is built tough and priced well. The exciting feature is that you will be able to take this production Jaw Rock Crusher straight from the shipping container and be using it in less than 30 minutes. NO WASTED TIME FINDING THE RIGHT ENGINE, SHEAVES, PULLEYS OR BELTS - JUST OPERATE THE MACHINE.

Features:

Specs:

Request a Quote

Description:

The GME10 Jaw Rock Crusher is a rock crusher that is designed to take larger rock and crush them down to 1" (25mm) or smaller to further be reduced by the GME Hammer Mill for gold milling sites. This crusher is also used by Contractors and Landscapers to crush rock for demolition or to create a specific product for use.

This jaw crusher is able to crush rock / ore up to 8" (205mm) in a very productive manner. The jaw rock crusher is built tough and priced well. The exciting feature is that you will be able to take this production Jaw Rock Crusher straight from the shipping container and be using it in less than 30 minutes. NO WASTED TIME FINDING THE RIGHT ENGINE, SHEAVES, PULLEYS OR BELTS - JUST OPERATE THE MACHINE.

Features:

- The GME10 Jaw Rock Crusher is an assembled jaw crusher that is ready to use immediately upon receipt.

- The Jaw Rock Crusher is able to crush material up to 8" (205mm)

- The Jaw Rock Crusher is able to adjust the final output size from 1/4" (6mm) to 3" (76mm)

- The Jaw Rock Crusher can be fitted with an electric motor, gas engine, diesel engine or no engine

- The flange and pillowblock bearings are the top of the line Blue Brute Bearings; these rugged bearings are used in the most harsh testing environments like rock crushing

- The shaft is 2.4" (60mm) at the cam shaft and 2" (50mm) at the drive shaft

- The jaw rock crusher wear plates are 3/4" (19mm) and are made of a hard faced 450 Brinnel Hardness Material. Also available is an upgraded cast manganese / chrome wear plates.

Specs:

- Drive System: 20HP Gas Engine / 18HP Diesel Engine / 10HP Electric Motor

- Height: 48" (1220mm)

- Width: 32" (812mm)

- Length: 56" (1422mm)

- Weight: approx. 950 pounds (430kg)

- Jaw Size: approx. 10" (254mm) wide x 4 to 6" (102 - 152mm) deep

“The GME10-jaw crusher we bought from GME has been a huge asset to our solid surface recycling program. We now can avoid high disposal fees at our landfill and resell it as landscaping rock.”

-Chad / Owner at Chads Tile and Granite

“We bought both the GME10 and GME14 along with two ORO concentrators. The system GME designed for us has proven to be very effective and runs at a very high production rate for a small scale mill. We couldn’t be more pleased.

-Steve T.

“I bought a cheaper hammermill also made in the USA and had nothing but problems. We couldn’t run more than an hour or two without breaking down and replacing hammers/chain. Eventually the machine literally wore itself out and we were at a standstill. I didn’t have a crusher and had two tons of ore sitting on the ground. Brock told me to bring the ore by and we crushed it with the GME10 and GME14 in a little over an hour. I bought both crushers a week later and haven’t had any problems since. They are true production machines.”

-Nathan Freeze

Owner, IBC Ent.

Gallery

Click on an image below to view full size & scroll through all. Click here to see more photos.